Automation

Automation Consulting

Antogatva’s extreme automation consulting services enable organisations, to move beyond simple task automations to handling high-profile, customer-facing and revenue-producing processes with built-in adoption and scale. You can create connected, intelligent, end-to-end processes, underpinned with exponential technologies and trust. With the seamless orchestration of work across automation equipments, and your human workforce, enterprises can drive adaptive and flexible business models that enhance efficiency and productivity.

We provide a holistic approach to automation with a framework designed to deliver value fast. We meet you where you are, from strategy and roadmap design to running engagements that support automation programs at scale, comprising the below.

- Distributed Control System (DCS)

- Safety Instrumented Systems (SIS)

- Advanced Process Control (APC)

- Data Acquisition and Monitoring

- Alarm Management

- Inventory Management

- Reporting and Analytics

- Cybersecurity Measures

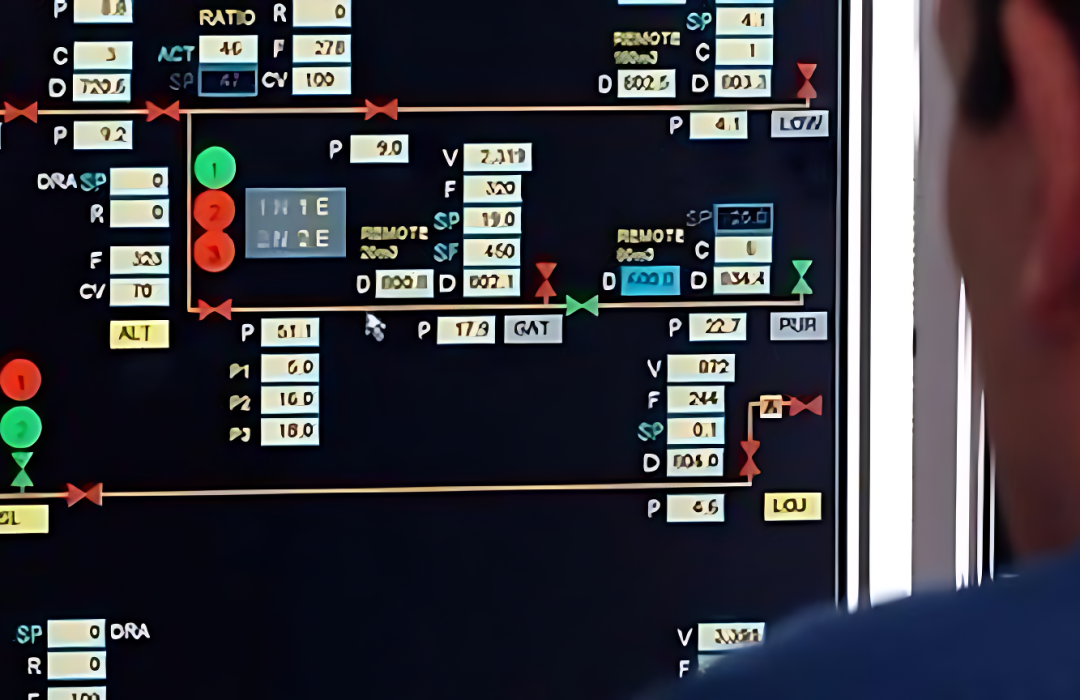

Distributed Control System (DCS)

A Distributed Control System or DCS is a computerized system that automates industrial equipment used in continuous and batch processes, while reducing the risk to people and the environment. DCSs use a communication network to facilitate data exchange and coordination among controllers. Network protocols used in DCSs include Ethernet, Fieldbus, Controller Area Network Bus (CANbus), ControlNet, DeviceNet, and INTERBUS

Safety Instrumented Systems (SIS)

In functional safety, a safety Instrumented system (SIS) is an engineered set of hardware and software controls which provides a protection layer that shuts down a chemical, nuclear, electrical, or mechanical system, or part of it, if a hazardous condition is detected.

Advanced Process Control (APC)

Advanced process control (APC) refers to several proven advanced control techniques, such as feedforward, decoupling, and inferential control. APC can also include Model Predictive Control, described below. APC is typically implemented using function blocks or custom programming capabilities at the DCS level.

Data Acquisition and Monitoring

"Data acquisition and monitoring" refers to the process of collecting data from physical systems using sensors and then continuously observing and analyzing that data to track performance, identify potential issues, and make informed decisions, often used in industrial settings to monitor equipment health and optimize processes; essentially, it involves capturing real-time data from various sources and actively watching it to detect changes or anomalies.

- Alarm Management

- Inventory Management.

- Reporting and Analytics.

- Cybersecurity Measures

Alarm Management

Alarm management refers to the effective design, implementation, operation, and maintenance of industrial manufacturing/process plant alarms. Alarm management is necessary in a process plant environment controlled by an operator using a control system, such as a DCS, or a Programmable Logic Controller (PLC).

Inventory Management

Inventory management refers to the process of storing, ordering, and selling of goods and services. The discipline also involves the management of various supplies and processes. One of the most critical aspects of inventory management is managing the flow of raw materials from their procurement to finished products.

Reporting and Analytics

Reporting is the process of gathering and presenting data in a structured format such as graphs and tables. Organizing information in predefined KPIs and metrics makes it easier for you to understand what is happening. Analytics is the process of analyzing your data to identify patterns and gain insights.

Cybersecurity Measures

Cybersecurity measures are steps taken to keep computers, networks, and data safe from hackers and other online threats. They include tools like firewalls and antivirus software, as well as best practices like controlling access to sensitive information and training employees to spot potential risks.